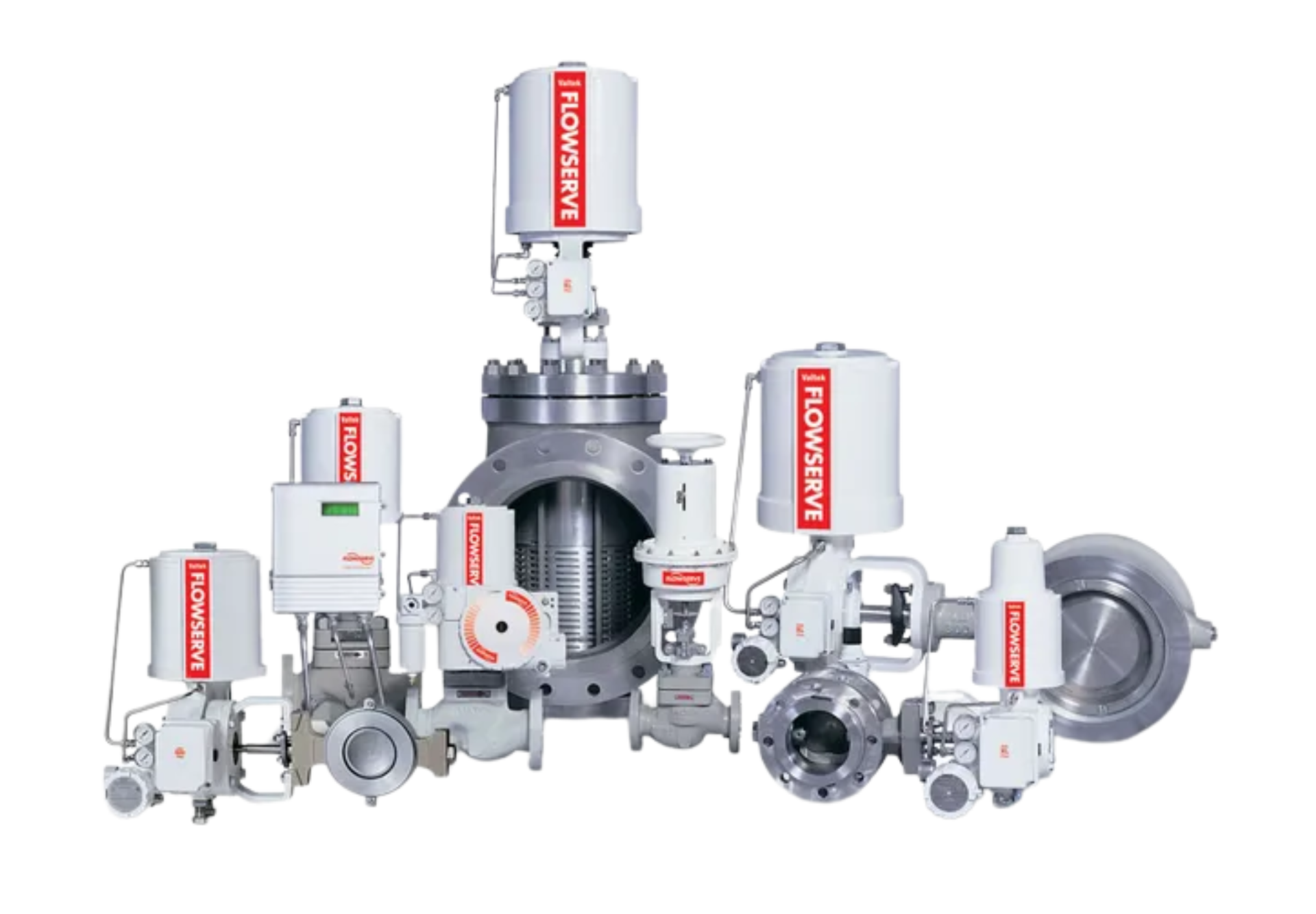

Flowserve Valtek Control Valves –

Precision Engineered for Performance

TVC proudly supplies the Flowserve Valtek range of control valves, renowned for their reliability, precision, and versatility across demanding applications.

The range includes:

•Mark One linear globe valves – ideal for accurate control in a wide range of process conditions.

•Rotary eccentric plug valves – combining tight shutoff with excellent throttling performance.

•High-performance and triple-offset butterfly valves – engineered for large flow capacities, offering a compact, cost-effective solution with reliable tight shutoff and control.

•Segmented ball valves – offering high rangeability and control in compact rotary designs.

•Survivor slurry valves – engineered for abrasive mining and slurry services.

•Cryogenic valves – designed for ultra-low temperature applications in LNG and gas processing.

From general process control to severe service conditions, Valtek valves deliver proven performance, supported by Flowserve's global engineering and innovation.

Flowserve Valtek Control Valves –

Precision Engineered for Performance

TVC proudly supplies the Flowserve Valtek range of control valves, renowned for their reliability, precision, and versatility across demanding applications.

Key Markets for the Mark 6 Cryogenic Control Valve

1. Liquefied Natural Gas (LNG)

2. Industrial Gas Production

3. Cryogenic Storage and Transfer Systems

For more information on sizing, materials, or specific gas compatibility, please contact our technical sales team.

The range includes:

- Mark One linear globe valves -

ideal for accurate control in a wide range of process conditions

- Rotary eccentric plug valves -combining tight shutoff with excellent throttling performance

- High-performance and triple-offset butterfly valves - engineered for large flow capacities, offering a compact, cost-effective solution with reliable tight shutoff and control.

- Segmented ball valves -

offering high rangeability and control in compact rotary designs

- Survivor slurry valves -

engineered for abrasive mining and slurry services

- Cryogenic valves - designed for ultra-low temperature applications in LNG and gas processing

From general process control to severe service conditions, Valtek valves deliver proven performance, supported by Flowserve's global engineering and innovation.

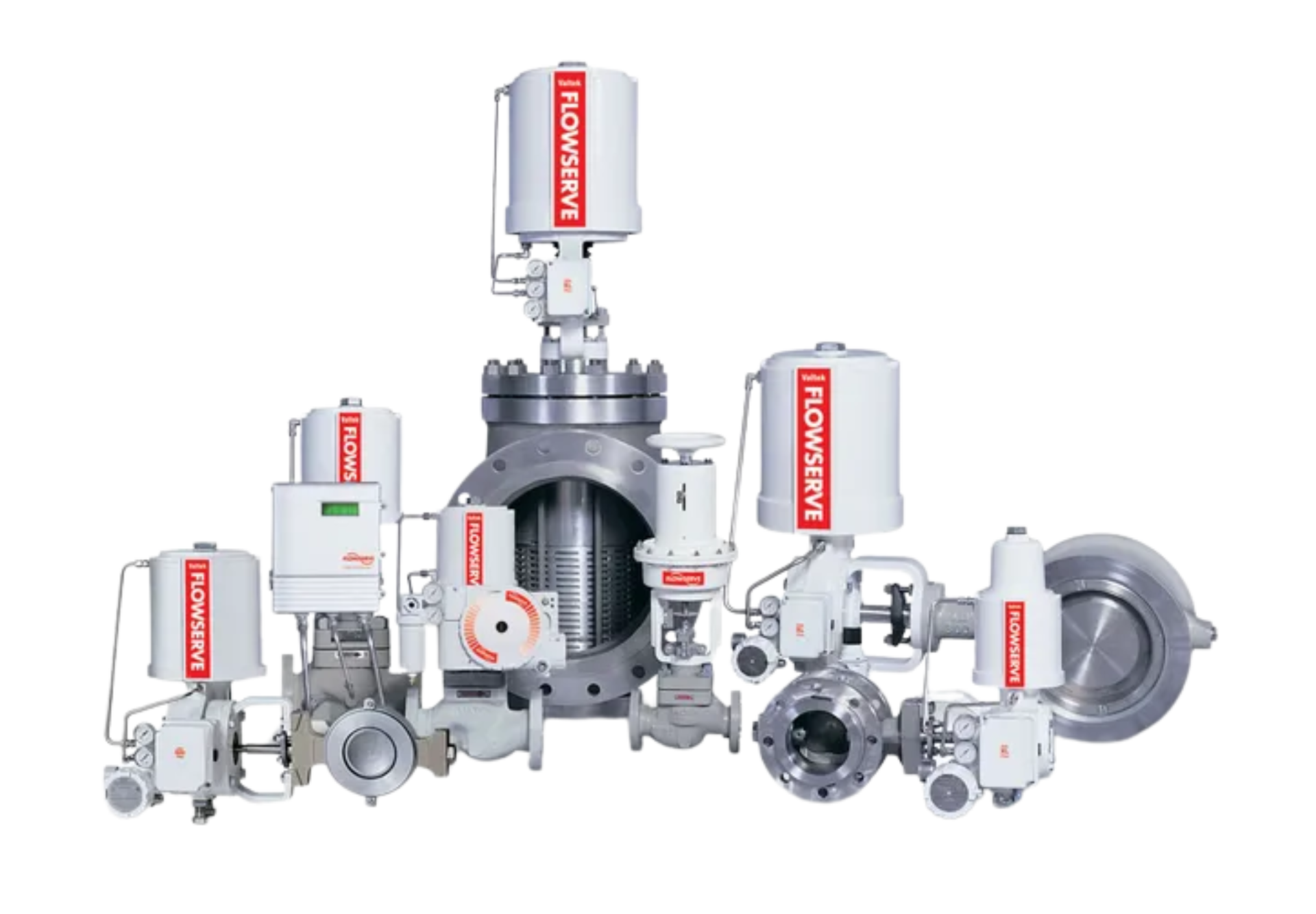

Flowserve Valtek Control Valves –

Precision Engineered for Performance

TVC proudly supplies the Flowserve Valtek range of control valves, renowned for their reliability, precision, and versatility across demanding applications.

Key Markets for the Mark 6 Cryogenic Control Valve

1. Liquefied Natural Gas (LNG)

2. Industrial Gas Production

3. Cryogenic Storage and Transfer Systems

For more information on sizing, materials, or specific gas compatibility, please contact our technical sales team.

The range includes:

- Mark One linear globe valves – ideal for accurate control in a wide range of process conditions.

- Rotary eccentric plug valves – combining tight shutoff with excellent throttling performance.

- High-performance and triple-offset butterfly valves – engineered for large flow capacities, offering a compact, cost-effective solution with reliable tight shutoff and control.

- Segmented ball valves – offering high rangeability and control in compact rotary designs.

- Survivor slurry valves – engineered for abrasive mining and slurry services.

- Cryogenic valves – designed for ultra-low temperature applications in LNG and gas processing.

From general process control to severe service conditions, Valtek valves deliver proven performance, supported by Flowserve's global engineering and innovation.

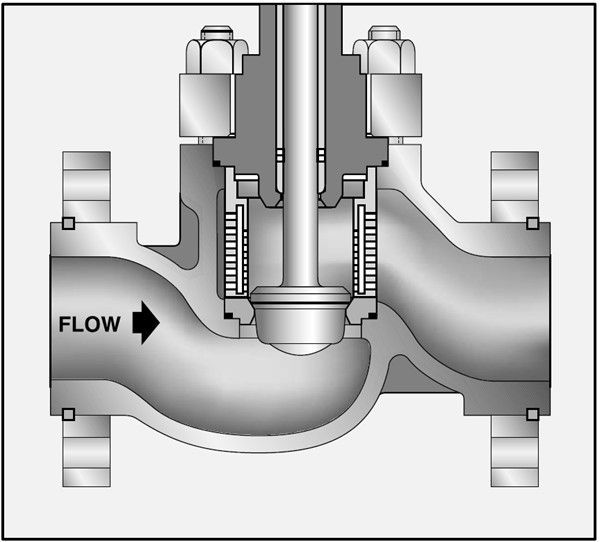

Mark 1 Control Valves

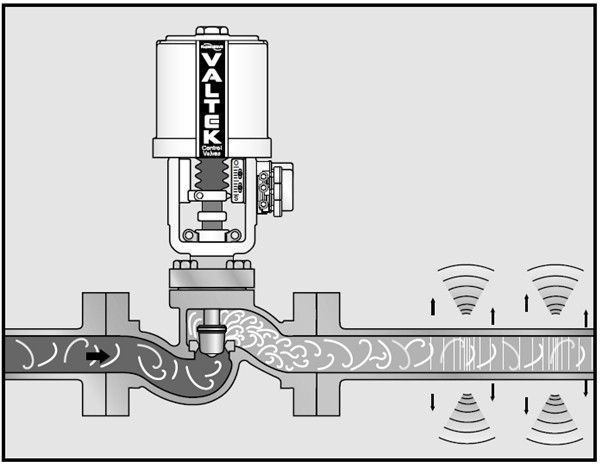

Valtek Mark One – Precision Globe Control Valve for Demanding Applications

The Flowserve Valtek Mark One globe control valve is engineered for exceptional performance in both liquid and gas service. Its robust design delivers precise flow control, excellent reliability, and reduced total cost of ownership.

Designed for long-term durability and ease of maintenance, the Mark One allows for fast, straightforward servicing with minimal downtime. The valve is equipped with a high-thrust spring-cylinder actuator that ensures:

•Superior positioning accuracy and repeatability

•High stiffness to resist process disturbances

•Reliable operation even under demanding conditions

Available in globe and angle body configurations, the Mark One supports a wide range of trims including anti-cavitation and low-noise solutions — making it ideal for everything from general process control to severe service applications.

For more information or sizing assistance, please contact our sales team.

Mining

Power

Geothermal

Petrochemicals

Oil & Gas

Pressure Swing Adsorption (PSA)

Food & Beverage

Chemical

Pulp & Paper

Steel & Primary Metals

Corn Wet Milling & Ethanol

Concentrated Solar Power (CSP)

Water Management

Wastewater

Agriculture & Irrigation

Other Industries

IS0 9001:2008

PED Directive 97/23/EC (PER)

API 607 Fire Safe

ATEX Directive 94/9/EC

ASTM B16.5

Size Range:

0.5 to 36

Pressure Class Range:

150 to 4500

Globe Control Valve

Angle Body Control Valve

Severe Service

Anti-Cavitation

Noise Abatement

Erosion Control

Fugitive Emissions

Butterfly Valves

Valtek Rotary Control Valves – Versatile Solutions for Precision Flow Control

Our Valtek rotary control valve offering includes high-performance butterfly valves, segmented ball valves, and eccentric plug valves, engineered to handle a wide range of flow control applications across various industries.

These rotary valves deliver reliable performance, excellent rangeability, and compact designs ideal for tight installations. Whether you require tight shutoff, control of abrasive media, or high-capacity flow regulation, Valtek rotary valves provide the flexibility and durability your plant demands.

For technical support or to discuss your specific application, please contact our sales team. We're here to help you select the right solution.

Mining

Power

Geothermal

Petrochemicals

Oil & Gas

Pressure Swing Adsorption (PSA)

Food & Beverage

Chemical

Pulp & Paper

Steel & Primary Metals

Corn Wet Milling & Ethanol

Concentrated Solar Power (CSP)

Water Management

Wastewater

Agriculture & Irrigation

Other Industries

ASME B16.34

API 609

ISO 15848-1

API 607

ISO 10497

Size Range:

NPS 3 to 60

Pressure Class Range:

ANSI 150–1500

Seating:

Laminated graphite/metal or solid metal seat

High Performance Butterfly Valves

Triple Offset

Lug Type

Wafer Design

Double Flanged

Teflon Lined

📄 Valtek® Valdisk™

📄 Durco® BTV-2000 Valve Lined Chemical Service Valves

📄 Durco® TX3 Triple Offset Butterfly Valve

No video available yet.

MaxFlow 4 Eccentric Plug Valve

The Valtek MaxFlo 4 eccentric rotary plug control valve is for applications demanding higher rangeability, precise control and higher flow capacity.

Mining

Power

Geothermal

Petrochemicals

Oil & Gas

Pressure Swing Adsorption (PSA)

Food & Beverage

Chemical

Pulp & Paper

Steel & Primary Metals

Corn Wet Milling & Ethanol

Concentrated Solar Power (CSP)

Water Management

Wastewater

Agriculture & Irrigation

Other Industries

ASME (B16.34, B16.10, B16.25)

PED, DIN, CRN, ISO, NACE, EN

Size Range: NPS 1–12

Pressure Class: ASME 150–600

Seating: Metal or soft

With NR Diaphragm, VR Piston, SuperNova Rack & Pinion

ShearStream Segment Ball Valve

The Valtek ShearStream™ is a segmented, ball control valve that provides exceptional control and rangeability for the process industries.

Power

Chemicals

Water Management

Oil & Gas

Midstream Transportation

General Industries

Pulp & Paper

ASME (B16.34, B16.10, B16.25)

PED, DIN, CRN, ISO, NACE, EN

Size: NPS 1–16

Pressure Class: 150–600

Seating: Metal or soft

—

📄 Documents will be added soon.

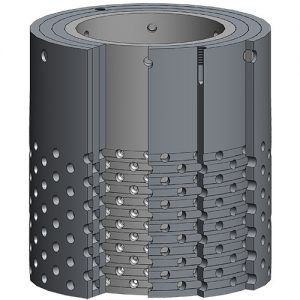

Severe Service Anti-Cavitation Trim

Engineered for Severe Service – Cavitation-Resistant Trim Solutions

One of the key advantages of Flowserve control valves is the wide selection of severe service trims designed to meet the most demanding plant conditions. In liquid applications with high pressure drops, cavitation can cause serious damage to valve bodies and internals. Flowserve's advanced trim technologies are specifically engineered to eliminate cavitation and ensure long-term performance.

These trims make our valves the ideal choice for critical applications such as:

•Pump Recirculation Systems

•Boiler Feedwater Control

•Condensate and Flashing Services

•Level Control in High-Pressure Vessels

•And many other challenging process environments

For expert guidance on severe service solutions, please contact our sales team.

Flowserve Noise Trim Solutions – Engineered for Quiet, Reliable Operation

In gas and steam services with high-pressure drops, control valves may generate excessive noise that can:

·Exceed occupational health and safety thresholds

·Cause vibration and damage to surrounding equipment

·Disrupt plant operations or nearby environments

To address these challenges, Flowserve offers advanced noise attenuation trims — including MegaStream™, ChannelStream™, and Multi-Z™ — designed to reduce aerodynamic noise through multi-stage pressure reduction and optimized flow path control.

Typical Applications Requiring Noise Trim:

1. Steam Letdown Systems

2. Turbine Bypass and Desuperheater Valves

3. Compressor Anti-Surge and Recycle Valves

4. Natural Gas and Hydrocarbon Vapor Control

5. Boiler Start-Up Valves

Flowserve's noise trim technologies are proven to significantly reduce sound pressure levels while protecting both personnel and plant infrastructure. For guidance on selecting the right trim for your application, contact our technical team.

Specialty Control Valves – Engineered for Demanding Applications

At TVC, we offer a range of specialty valves designed to handle the most challenging process conditions:

·Survivor Valve

Purpose-built for highly erosive and flashing services, the Survivor valve is a trusted solution for demanding applications such as autoclaves and slurry lines, where standard valves fail.

·Anti-Surge Valve

Our advanced anti-surge valve features cutting-edge technology that eliminates the need for external boosters and accessories. This streamlined design ensures faster response, easier tuning, and reduced maintenance—providing superior protection for compressors against surge events.

·Multi-Z Valve

The Kämmer Multi-Z is an axial, multi-stage control valve engineered to manage extremely high pressure drops, even in fluids containing suspended solids. It has proven performance in critical services such as pump recirculation and boiler feedwater control in power generation plants.

For more information or assistance in selecting the right valve for your application, please contact our sales team.

Flowserve Valtek Mark 6 – Precision Control for Cryogenic Applications

The Flowserve Valtek Mark 6 cryogenic control valve is purpose-built for ultra-low temperature service, making it the ideal solution for processes involving liquefied gases. Its extended bonnet design insulates the actuator from extreme cold, ensuring safe, reliable performance and long service life in demanding cryogenic conditions.

Key Markets for the Mark 6 Cryogenic Control Valve

1. Liquefied Natural Gas (LNG)

2. Industrial Gas Production

3. Cryogenic Storage and Transfer Systems

For more information on sizing, materials, or specific gas compatibility, please contact our technical sales team.

LNG

Oxygen

Nitrogen

Power

Mining

Petrochemicals

Oil & Gas

Food & Beverage

IS0 9001:2008

PED Directive 97/23/EC

ATEX QAN Quality Registration

IECEX QAR Quality Registration

SIL Certification

CRN Certification (Canadian Registration)

EMC Directive 2004/108/EC

ATEX Directive 94/9/EC

CE Mark

SSOV (FM Safety Shut-off Valve Fuel Service

API 607 Fire Safe

-196°C to 400°C

(-320°F to 752°F)

Size Range: DN 15 to 300; NPS 1/2 to 12

Pressure Class Range: PN 10 to 400; Class 150 to 2500

Globe Body Pattern

Angle Body Pattern

Butt Weld, Socket Weld or Integral Flange

No video available.