Kämmer Multi-Z® – Engineered for Severe Service and High Pressure Drop Applications

The Kämmer Multi-Z® control valve is purpose-built to manage extremely high pressure drops, especially in applications where entrained solids and cavitation pose serious challenges. Its multi-stage axial flow path gradually reduces pressure across multiple stages, effectively eliminating cavitation, minimizing erosion, and ensuring long-term reliability.

This flagship valve is a proven solution for critical services such as:

·Pump recirculation systems – where continuous flow at high ΔP can quickly erode standard valve trims

·Boiler feedwater control – ensuring stable, cavitation-free operation under high-pressure conditions in power generation environments

With a rugged design, customizable trim options, and superior performance in severe conditions, the Kämmer Multi-Z® sets the standard for reliable control in demanding applications.

For detailed specifications or sizing assistance, please contact our technical team.

Mining

Power

Geothermal

Petrochemicals

Oil & Gas

Chemical

Pulp & Paper

Water Management

Wastewater

Other Industries

IS0 9001:2008

PED Directive 97/23/EC

SIL Certification

CRN Certification (Canadian Registration)

ATEX Directive 94/9/EC

CE Mark

Globe/Angle Control

Valve, High Performance

Severe Service

Anti-Cavitation

Noise Abatement

Errosion Control

Fugitive EmissionsASME 300 pressure class

No video available.

Flowserve Kämmer SmallFlow Control Valves

Engineered for precision in low and micro flow applications.

Flowserve Kämmer's SmallFlow control valves are designed for exceptional performance in virtually all low-flow and micro-flow scenarios. These compact valves are widely used in laboratories, pilot plants, and small-scale production facilities where precise fluid control is essential.

Typical applications include accurate fluid injection in process systems — such as dye dosing in paper and textile manufacturing, fuel oil burner control, additive injection in refineries, desuperheater spray systems, and R&D setups requiring precise control of flow, temperature, or pressure.

Mining

Power

Geothermal

Petrochemicals

Oil & Gas

Chemical

Pulp & Paper

Water Management

Wastewater

Other Industries

Standards and Certifications

IS0 9001:2008

PED Directive 97/23/EC

SIL Certification

ATEX Directive 94/9/EC

CE Mark74510

Globe Control Valve

Low Flow / Microflow

Bellows Seal

Anti-Cavitation

Low Temperature

Fugitive Emissions

No video available.

Kämmer Series 132000 – Lined Control Valves

Corrosion-resistant control for aggressive media

The Kämmer Series 132000 is a PTFE-lined globe control valve designed for highly corrosive and aggressive chemical applications. Ideal for use in the chemical, pharmaceutical, and pulp & paper industries, this valve offers exceptional resistance to acids, alkalis, and other harsh media. Its compact, robust design ensures reliable performance, easy maintenance, and long service life.

Mining

Power

Corn Wet Milling & Ethanol

Petrochemicals

Oil & Gas

Chemical

Pulp & Paper

Water Management

Wastewater

Other Industries

Standards and Certifications

IS0 9001:2008

PED Directive 97/23/EC

SIL Certification

CRN Certification (Canadian Registration)

ATEX Directive 94/9/EC

CE Mark74510

Globe Control Valve

High Performance

Bellows Seal

Anti-Cavitation

Low Temperature

Fugitive Emissions

No video available.

Kämmer ™ Food-Grade Control Valves

Precision flow control for hygienic applications

Designed for food and beverage production, Kämmer food-grade valves offer precise control, cleanability, and full compliance with hygienic standards. Ideal for dosing, blending, and CIP/SIP processes in dairy, brewing, and ingredient handling.

Our hygienic valves are trusted in food processing plants worldwide — including installations where Krones systems are used — ensuring reliable, sanitary performance in critical applications.

Chemical

Pharmaceutical

General Industries

Food & Beverage

Other Industries

Chemical

Pulp & Paper

Water Management

Wastewater

Other Industries

Standards and Certifications

IS0 9001:2008

PED Directive 97/23/EC

SIL Certification

CRN Certification (Canadian Registration)

ATEX Directive 94/9/EC

CE Mark

3A approved

EHEDG

Globe Control Valve

Food & Beverage

Aseptic & Ultra Clean

Bellows Seal

Fugitive Emissions

No video available.

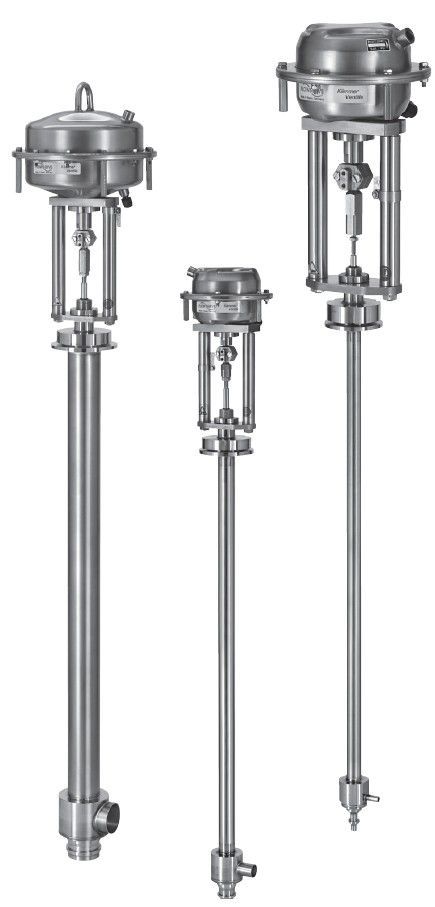

Kämmer Tank Bottom Valves

Reliable control and clean discharge from vessels

Kämmer tank bottom valves are specifically designed for installation at the base of process vessels and tanks to ensure precise, clean, and safe discharge or sampling of liquids. Their flush-mount design eliminates dead space, minimizing product retention and enabling complete drainage — essential for sanitary, high-purity, and critical process applications.

These valves are ideal for industries such as pharmaceuticals, biotechnology, fine chemicals, and food & beverage, where cleanliness, corrosion resistance, and operational reliability are paramount.

Pharmaceutical

Chemical

Food & Beverage

Biotech

Specialty Chemicals

ISO 9001:2008

FDA Compliant

CIP/SIP Compatible

ATEX Certified

EHEDG Design

3A Certification (Optional)

Manual or Pneumatic Actuation

Flush Mount

Bottom Outlet

Dead-Space-Free Design

PTFE, PFA, or Alloy Options

No documents available.

No video available.

Kämmer Cold Flow Control Valves

Precision control in cryogenic and low-temperature applications

The Kämmer Cold Flow valve is engineered for demanding cryogenic and low-temperature services, ensuring reliable performance in temperatures as low as -196°C. With extended bonnets, specialized materials, and tight shutoff capability, it is ideal for applications involving liquefied gases such as nitrogen, oxygen, argon, and LNG.

These valves are commonly used in industries such as industrial gas, aerospace, and energy, where safety, precision, and durability are critical in low-temperature environments.

LNG Terminals

Air Separation Plants

Petrochemical

Hydrogen Processing

Aerospace Applications

-196°C to +65°C Temperature Range

ISO 28921-1/2 Cryogenic Testing

Extended Bonnet Design

Helium Leak Test Certified

Fire Safe Design (API 607)

Globe/Angle Valve Designs

Top-Guided Trim

Manual or Actuated

Stainless Steel or Alloy Construction

Soft or Metal Seat Options

No documents available.

No video available.